How to choose a cost-effective water jet

We need to clarify that cutting efficiency includes the quality of the cutting surface and cutting speed, and the two are in reverse relationship, which means that the higher the quality of the cut, the more...

Firstly, we need to clarify that cutting efficiency includes the quality of the cutting surface and the cutting speed, and the two are in a reverse relationship. That is to say, the higher the quality of the cut, the lower the general cutting speed. So when you go to different water knife manufacturers for inspection, you can compare more about which speed is faster for the same material under the same cutting quality conditions; Whose cut is better at the same cutting speed. Secondly, it is more durable, mainly focused on the core of the water jet - the high-pressure system. The quality of components such as high-pressure cylinders, energy accumulators, high-pressure plungers, one-way valve body plugs, high-pressure seals, and one-way valves directly determines the failure rate of water knives. The longer the material and service life of these components, the better. In addition to these two points, Shenyang Guanghui Water Cutting Factory reminds you that the maintenance and repair costs should also be noted. Because although water knives do not require a lot of consumables, they also have to be considered in use, not only depending on the price of a single piece, but also on the service life.

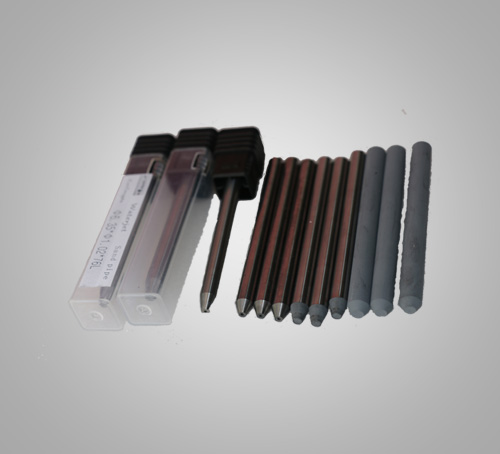

Xiamen Xinyongde Precision Tools, acting as an agent for importing multiple brands such as Ellen Bradley, Kenna, Senla Tianshi, etc. of water knife cutting head quicksand pipes, with ultra precision and extraordinary service life, ensuring quality and excellent price, providing blank and semi-finished materials. It is an important accessory and ideal product for water knife cutting machines.

Our company adheres to the principle of "sustainable operation and honest service".